Cali392JL

Well-known member

- Joined

- Sep 21, 2022

- Messages

- 174

- Reaction score

- 165

- Location

- Los Altos, CA

- Current Rides

- 2022 White JL 392XR

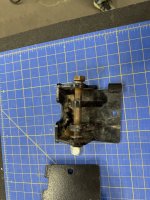

I have a 2022, 392JLU running a metalcloak 3 1/2 inch lift, all metal cloak steering with fox ATS, and a few other goodies. I've been focusing on armor lately and have the metalcloak, skid plate, rockhard sliders, metalcloak differential skids, and now I want to add control arm skids. From what I am reading, the Weldon skids can make it difficult to remove the control arms for servicing. I was leaning toward Bolt on skids, but from what I have heard the rock hard Bolt on skids frequently, have issues with properly, locking down the control arm with the bolt pinch force. I'm wondering if people know of any other options that work well, I would consider weld on if people can chime in and alleviate my concerns about removal and servicing of the control arms easily.

I am wanting to put skids on both the front and rear's however, in the rears, I am running the metalcloak lower shock relocation bracket. Most of the Bolton skids I see you for the back also include provisions for the shock mound, but mine is no longer in that same position, and I would like to have something that only protects the control arm. Appreciate any heads up if people are aware of some thing that would work well.

I am wanting to put skids on both the front and rear's however, in the rears, I am running the metalcloak lower shock relocation bracket. Most of the Bolton skids I see you for the back also include provisions for the shock mound, but mine is no longer in that same position, and I would like to have something that only protects the control arm. Appreciate any heads up if people are aware of some thing that would work well.